Greetings:

Seeking words of wisdom regarding ' off set center wheel servicing '. I thought sweep second wheels were a challenge to understand until......I began dismantling my Dad's old Commander D ? with 10coac mvmt. From what I can surmise it is a friction fit to be treated like a short canon pinion for disassembly etc. I am a bit stymied as to how to proceed. Any advice or experience would be bwelcome. Thanks.

Pinout

There are a few versions of this, but essentially the indented cannon pinion (or friction system) is absent from this design if memory serves. In some other brand iterations, the movement utilizes both an indented cannon pinion and the third wheel friction fit pinion with a spring loaded indirect minute wheel. Where the Cannon pinion is completely absent from the centre shaft, nomenclature from the various brands lists the wheel as simply a centre wheel, even though it really isn't. The Centre Wheel (in the absence of a Great Wheel) is the one under the plate, not on top of it, but I digress...

These can be daunting if you are unfamiliar, and if you don't have the proper tools to do it, I do not advise attempting to disassemble the movement. Friction fit parts have to be separated carefully and then pressed back together carefully, observing height tolerances and clearance.

I have had success in tightening the friction fit pinion, but it is fussy and you need exactly the right set of punches/stakes. Ideally, you replace the wheel and pinion. Ideally, cannon pinions are to be replaced, but in many old vintage watches this is no longer possible and cannon pinion tightening devices are used. These can range from simple cutter-style pliers with jaw limiters to single small stakes specifically for the purpose.

This is assuming of course, that the CP or the friction pinion are loose. They also have to be lubricated rather precisely, or they will get loose in a big hurry. I often see these assembled incorrectly, where the indirect minute wheel is on the wrong side of the tension spring, meaning the motion works will not function properly even though the watch is running well.

Omega does this as well in their 1000 series from the 70's, and I am not crazy about the design in general. I once asked my watchmaking prof what his favourite movement was, taking into consideration ease of repair and general design characteristics.

He said the AS 2066, which is derived from earlier iterations like the AS1712. In Bulova world, the AS 2066 is an 11ULACD.

As with any repair trade, nothing is really a problem as long as you have the brand new spare parts. It is when you have to improvise or especially make a part, that classical watchmaking is used. During our practical exams, we had to fabricate parts from scratch as well as repairs to certain parts, which involved tightening things like this.

EDIT:

I should add that oftentimes the wheel and pinion are NOT separated, and the movt is cleaned with the wheel still installed in the main plate. This avoids having to mess around with it, but is less than ideal with respect to proper cleaning, but if the wheel and pinion are correctly and precisely lubricated after, it may be the only route to take, especially if there is no way to disassemble or repair the part, or if there is no new part available. If, after cleaning and lube and re-assembly of the movt yields a watch that does not run because the pinion is slipping, you will have no choice but to take it apart again and either replace the part or tighten the pinion on the wheel.

Howdy Rev Rob,

Thanks for enlightening me on this design. I tried in vain to attach photos so you could see it.

This one does have a normal positioned canon pinion with detent as well. It also has the spring under the minute wheel. Surprise to me. Do you know which side of the spring the shaft should be placed? Happened so quick I can only guess right now.

Interesting regarding the 2066. I'll be curious to get hold of one to look at if possible.

After reading your message I think I'll press the 'Easy Button' and leave it intact during cleaning,etc. Seems the better part of valor at this stage to go low risk. Went that route and left the wheel intact on my first sweep second wheel. Removed it on the next watch. Scary procedure. Do you have any words of wisdom on the safest way to handle that?

Anyhow,thanks again. Appreciate it. Wish I could have sent pics but again the software exceeds operator.

Happy New Year!

John T.

Hey John,

The spring must hold the minute wheel's lower pivot towards the cannon pinion, as in there must be tension directed at the centre, otherwise there will be no drive or intermittent drive to the motion works and the hands will either not move at all or be wildly behind.

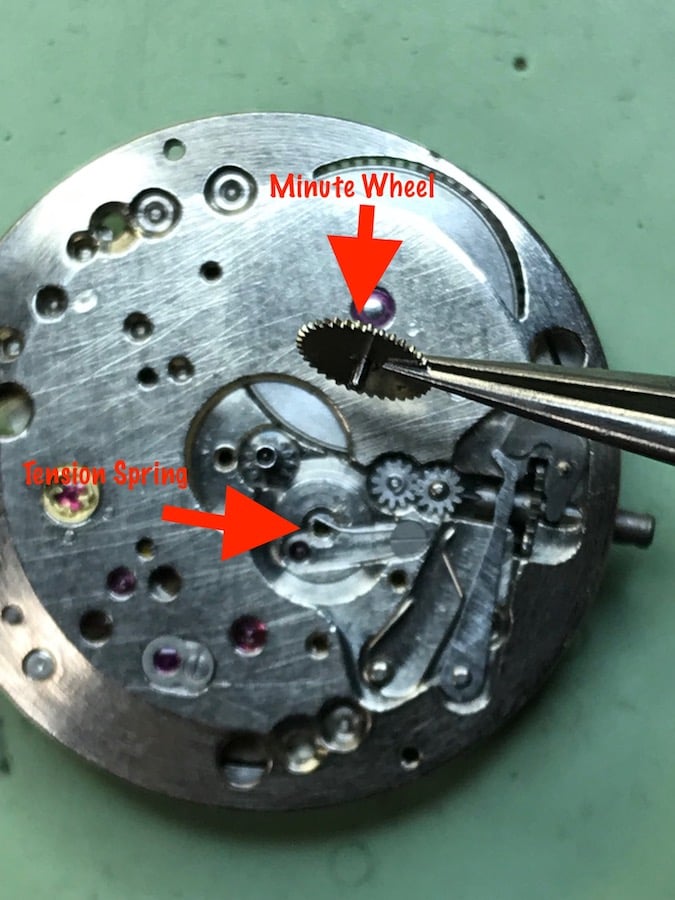

There is a pic on the subject that I posted here, I'm just trying to locate it.

Ok, this is one of them. The spring must push the minute wheel UP, so it exerts pressure on the CP.

I don't remember what thread this was in or what movt we are looking at. As you can see, there is an indented Cannon Pinion as well as the Third Wheel friction pinion next to the Intermediate setting wheel. I'm pretty sure I tightened this one, but I could be wrong about that.

In most watches, the CP is friction fit, either by indenting, or what I call the 'Grok' type. (Looks like a 45 rpm record insert) The CP drives the hands: CP turns the Minute Wheel, which turns the Hour wheel, and the hands turn. If the CP is worn out, the watch loses time and you may even see the minute hand slip visibly if you tilt the watch. In some cases the CP is free wheeling and the pinion of the Third Wheel drives the motion works. When the watch is in setting mode, these will slip to allow the hands to move. As you can imagine, after many years of setting the time, or especially going around the dial to set the date (as in the non quickset date types) the CP gets worn out.

Rev Rob,

Yep that's the culprit! Thanks for enlightening me on how that all works.

I am puzzled by all the variations on applied tension and the advantages versus the ole tried and true center wheel, in the center, with pinion. Can't grasp why the minute wheel spring is used vs wheel on post. I'm still hoping for that moment of clarity where it all makes sense. I suppose we all are at different levels.

Watched a video on You Tube on the servicing of an AS1900 which has the 3rd wheel friction pinion. Think I'll steer clear of that one.

Well, Thanks again and Happy New Year to you!

John T.

There are some very informative videos on Youtube now, it really is amazing.

It all boils down to design and patent, or in the case of certain companies, they seem to get bored and over-engineer EVERYTHING.

With the advent of QuickSet date functions, it was no longer necessary to spin the hands around to correct the date, so the wear to the CP was reduced, but it still is a source of higher than usual wear because it is metal-on metal, and a considerable amount of force is applied when setting the hands. Both the indented type and the Grok type (friction) seem to wear equally, so no advantages either way. The Grok is far more expensive to produce. In some movts, the CP is freewheeling, but something still has to grab/slip, so you end up with friction to run the hands and a means of defeating it to move the hands while setting.

Nowadays, most of the old patents are in public domain, including a lot of the ETA stuff, which is why you see far more Chinese versions of the ETA movts as well as the Sellita versions.

Supposedly, an indirect minute wheel moves the parts aside enough to allow for a larger balance, but then, so does making the movt slightly larger, so I don't know.

The 'Why' is sometimes just so they can be different, maybe while developing an in house calibre. I often look at the over-engineered Longines movts of the late 50's and wonder what the hell they were trying to accomplish, using five parts to accomplish the job of one...

I even asked a master watchmaker friend of mine, he said 'Who Knows?' So our answer is going to be.....

Illuminati.

In reply to Rev Rob, Wow, had to look by Pinout