hello i finished cleaning an 8ae the seller of the movement said the it was running fast..i cleaned oiled everything and the movement gains two to three minutes a day..i would like to get it down to atleast 1 to 2 mins a day..the regulator is all the way over to the slow position ...am wondering if i can try to put it beat or moving the collet,since i just got a beat tool if this will help..but then i think wasn't the watch already in beat...to my knowledge it hasn't be restaffed or anything...i guess a collet can maybe move after 50 some years...any suggestions???

First off 2 or 3 minutes a day fast is not that bad, but I can understand your wanting to try to get it better. Have you checked the hairspring where is passes through the regulator pins? Sometimes it ends up outside the pins instead of between them. The little bit of extra pressure on the hairspring can cause it to gain a bit.

Jay

99.9% of the time, hairspring manipluation is necessary when servicing a watch, especially a vintage watch. Your hairspring could be slightly magnetized, so demagging it wouldn't be a bad idea.

The hairspring, with no power to the escapement, ie: the power has been let down on the movt, (hold the stem and slightly wind the watch, and when the click clears the ratchet wheel, hold it out of the way with a tweezer point or pick, and slowly let the mainspring unwind) should be exactly in the middle of the space between the regulating pins. If it is not, it needs to be carefully adjusted so that it is. The best way to see how far out of beat it is, is with a timing machine, but sometimes you can hear the accent on the ticking when you hold it to your ear. To adjust the beat, a timing machine would be necessary. On old watches, with a non movable stud, the beat error must be corrected by removing the balance and rotating the collet with a special tool. Tiny adjustments are necessary, and it can only be checked with a timing machine. If the watch gains or loses in vertical positions relative to the dial up or dial down, you have positional errors that could be caused by many things, not the least being the distance between the regulating pins, the shape of the hairspring or centering, the terminal coil shape, the pinning point at the collet, and jewel shake throughout the train.

The watch's performance on the wrist will be the ultimate deciding factor, but without the watch in beat or the hairspring centered and in the middle of the pins, regulation will be problematic. Because of the many positions of your arm throughout the day, positional errors will determine the end result. The watch may run perfectly sitting flat, but positional variations will cause a poor result. A properly adjusted watch will have the regulator sitting roughly in the middle of the scale. Hard over on either side is not good. If you plan to get more involved with repair or regulation, etc, I would recommend getting a timing machine. The Chinese ones for $248 aren't exactly high quality, but will serve the purpose without breaking the bank for a Witschi. ($5K)

thanks everyone...i have checked the pins, but i guess i should put through the demagentizer...i do work next to my pc so that maybe have somekind of effect ..actually that timing machine was going to be my next item i buy..i am going to be getting soon..the movement runs good in all positions. and i don't see any major positional error...i was going to follow the steps in the bulova watchmaking book and then check the movement for a few days...but i will go over everything again...i just hope i don't make it worst....

Just a word on demagnetizers- Tunnel type do not work well on watches, they are designed to demag tools. What you want is a flat plate type instantaneous demagnetizer, like a Magna-Flux. The tunnel type may magnetize your watch to the point of seizing it. I recently had my own Magna Flux break down, and had to have it overhauled at an electronics shop, but found that my back up blue plastic demagger was a bit buggy to use. We had the same problem while at school, we tried to make do with a tunnel type, and it really screwed the watches up. I purchased a few old ones made by Troop-Balas, on eBay, and had them overhauled as they weren't working. The overhaul cost $100, but was well worth it, as a new watchmaker's demagger by Greiner/Vibrograf is $300. I did end up purchasing one of these also, I can highly recommend it, it works flawlessly and is made to last.

One thing that did come up in conversation this afternoon, was that if the watch in question is a non-shock type balance, which the 8AE certainly is, the cap jewel MUST be disassembled from the jewel setting and the setting properly cleaned. Intermittent problems occur when small amounts of old oil or dirt get stuck in the jewel setting. A lot of service places do a quick service and don't fully disassemble the balance, and 8 times out of ten you can get away with it, but sometimes you don't.

And an additional note- the timing machine will really open your eyes. What appears to be a watch running ok will be revealed to be what it actually is- positional variations, poor amplitude, damaged wheel teeth, out of beat, etc. An example would be, say the watch is gaining under ten seconds dial down on the machine, but in a vertical position it takes off to plus 120 seconds or loses 145 seconds. Not what I would call a good result at all. In almost all cases, this is caused at least in a major part by hairspring problems and balance out of poise.

Excellent point RevRob on the cap jewel. I've seen folks actually put oil on top of the cap jewels without removing them! Back to the gaining issue, in my experience when there is oil on the hairspring or it is magnetized the gain is a lot more than a couple of minutes a day. The gain ER is referring to is quite small which leads me to speculate that it is a relatively small hairspring issue requiring carefull manipulation, as you pointed out. Still another possibility is the mainspring. I have seen set mainsprings and wrong mainsprings cause a watch to run both too fast and too slow.

Jay

i was never told about the tunnel demag not really working on movements...it always seemed to work for me..i guess the i will also try removing the cap jewel...someone told me that with modern ultrasonics that you really don't need to remove the jewels..but since the cap jewels are different then the others you should..there could be so many problems..just even if i put the watch in beat it could still gain a minute or two...

And here's where I add my note on ultrasonics:

Ultrasonic cleaners, if used repeatedly on watch movt parts, can and will strip plating off the movts. This is especially true of vintage watches, where the watch has been serviced more than a few times in its history, and possibly cleaned with various solutions as well, including cyanide. This will all add up to the next use of the ultrasonic loosening the plating and it will come off like the dust off a moth's wing. It doesn't happen all the time, but it's happened to me a couple times in the last two years.

The jewels don't need to be removed except for the balance cap jewels, or the entire shock setting and cap jewel. Personally, I do not clean these in a cleaning machine at all, I hand clean them in hairspring cleaner. Also, ultrasonics will weaken older mainsprings, increasing the likelihood of breakage. This is especially true of clock springs, but also applies to blue watch mainsprings. I was told this by a master watchmaker, and Fellow of the BHI, and given this information, I suspect ultrasonics might disturb hairsprings also.

I don't use ultrasonics for cleaning watch movts, I use an L&R Master, which is just a three jar machine with heater and spinning basket.

And for hairsprings, simply being out of round or not perfectly centred around the staff will cause enough of a disturbance as to throw the regulator right off to the point where you have to push it all the way one way or the other. Hairspring manipulation is an extremely exacting task, and I hesitate to even suggest for someone to try it. It is very easy to completely destroy one.

Forgive the long posts, I don't normally go into detail like this, but Ellierose, you seem to be leaning toward learning the trade, so I am directing this toward yourself or anyone who wants to really get involved in watch repair.

In reply to And here's where I add my by Reverend Rob

FORGIVE the long posts? Dude, this is the sort of information people pay money for! I'm a hobbyist who does his own COAs because it's the only way I can afford to own more than a handful of watches, and hearing from an experienced watchmaker about the ins and outs of watchmaking is priceless!!!

Keep 'em coming!!!

In reply to FORGIVE the long posts? by Elgin Doug

Sorry! One more thing:

To remove the cap jewel, as you might suspect, is a fiddly process. The stud screw must be lossened, the stud pushed out of the stud holder, and the spring freed from the regulating pins, (some have a boot that must be rotated to release the terminal coil of the hairspring) and the hairspring and balance removed from the balance cock. (bridge) Some have the screws going in from the top, but a great many have them going in from underneath, and hence the need to remove the balance. These are very tiny screws, and taking them out is the easy part. Once you have cleaned the bearing jewel and the cap jewel, and placed a perfect oil drop on the cap jewel, you get to reassemble this little gizmo. It takes a finely honed and tiny screwdriver, as well as the fine Dumont tweezers number 5, to handle them. It helps to immobilize the balance cock upside down on a flat jeweller's anvil, stuck in a blob of Rodico. If you lose one of the screws, the balance may not be secure enough to operate with only one, as the regulator will twist the setting, rotating it on the one offset screw, smearing your carefully placed oil drop and ruining the whole setup.

thanks again i have gotten pretty good working and removing balance wheels from the balance cock,using the method you described with the rondco..also i have oiled shock protected balances before so i have some practice in dealing with very small jewels...also i use one dip on the hairspring and never tied putting in the ultrasonic..although i have done it with mainsprings..which now i guess i will try somthing else...i read about using a sometype of degreaser,putting on an lint free rag and cleaning the spring by hand,being careful not to deform it...i also don't put movements in a ultrasonic if they are really old or have anytype of plating coming off already...i just dip them in cleaner and do it completey by hand..i even peg out the jewels and brush the movements after putting them in the ultrasonic anyway...then clean anything left over with rondco..i am also looking in to cheap new movements to practice on, something i should have done awhile ago but i gotten pretty good at cleaning and assemblying but now i am on to staking staffs and posing...so instead of using nos parts that are expensive and hard to find..i am looking to cheat eta movements so i can practice on them,also [parts are cheap and pentiful...i gotten down removing the staffs and installing a new staff..thats is the easier part..its the other things like the rollet table breaking or the staff breaking in the table itself,that is what is giving me a hard time...i did a few start to finish and had them working in the movement..so i can do it but its hard,there is alot of varibles...in staking a staff...thanks rob for all you help and thanks also to everyone one esle how added to this topic

hello i finally was able to buy my timing machine, which has been a major help and very good investement..when i put the movement that was the topic here it ran at almost 3-4 minutes fast,which is pretty bad...and very low amplitude around 160 i followed most of the info that was replied to in this topic and some from other places..(also finding and understanding how the machine works,since the user manual doesn't really tell you everything,i guess the expect you to already know) so anyway after many adjustments the movement is now at 290-300 amp, and gaining only 25-30+sec a day which isn't perfect but extremely better than before...if i wasnt scared of breakng the the staff (which i always have the worst luck on these 8ae and ac movements ,in breaking the staff more than anyother of the same movement i worked on more than once) i could,maybe get a better reading...so i figured i would keep the memebers who chimed in an update and issue another thanks to all the help given to me and on behalf of anyone else who can use the vital info on this post...thanks again...

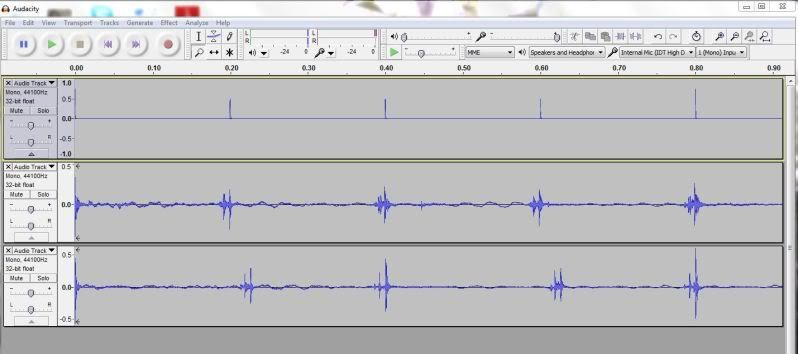

For those without a timing machine, there's a free software package called 'Audacity' that I use, with the built-in microphone on my laptop, to regulate my watches.

It displays sound levels over time, so you can record a minute of your watch running, and compare that to a 'click track' tha't set to place spikes every 0.2 seconds. After a minute, your watch's ticks will be ahead (fast) or behind (slow), and you can adjust and re-test.

It also allows you to determine whether the watch is in beat. If it is, the 'tick' and 'tock' should have exactly the same interval. If not, it's out of beat.

The top track is the computer-generated 'click track'. The second is an in-beat watch, the third is out of beat.

This doesn't provide amplitude, of course, or any of the other useful diagnostics you might get with a real timing machine, but you can't beat the price!